Introduction

Microvolume spectrophotometers rely on the surface tension of liquids to bridge the air gap between the upper and lower sampling surfaces. Erroneous measurements will occur if the air gap is not bridged with a liquid sample during the entire measurement cycle. This note will describe some common causes for the unbridged condition and how the DeNovix DS-Series 1 µL Spectrophotometers and DS-8X Eight Channel Spectrophotometers eliminate these concerns using SmartPath™ technology with Bridge Testing™ verification.

Causes of Unbridged Microvolume Measurements

Improper Sample Size

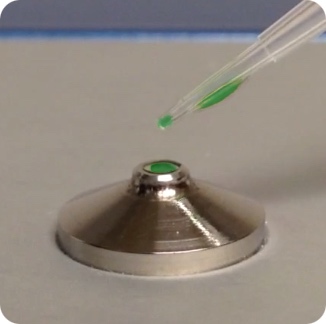

Sample pipetting errors can occur with surprising frequency and are often not noticed by the user. It is not uncommon to dispense significantly less than the desired sample size. The two main causes for this are (1) poorly fitting pipette tips that do not allow the plunger action of the pipettor to dispense the fluid completely and (2) samples that cling to the pipette tip instead of loading onto the sample surface (Figure 1). Purified proteins are an example of the type of samples that tend to adhere to a pipette tip rather than fully dispense onto the measurement surface.

Whatever the initial cause, the end result of a pipetting error is that less than the expected volume is delivered onto the sample measurement surface. Insufficient sample volumes can result in an unbridged condition on some spectrophotometers and produce erroneous measurement data. In many cases, the user will not realize reported sample concentrations are incorrect on these instruments because there is no indication that an unbridged measurement has taken place.

Surface Unconditioning

Many microvolume spectrophotometers exhibit a phenomenon, often referred to as “unconditioning,” where the sample surface loses its hydrophobic property. If this occurs, the sample will spread out (Figure 2a) on the sample surface instead of beading up (Figure 2b), making bridge formation impossible. This is usually caused by the routine use of detergent or solvent based buffers.

Regardless of the exact cause, the issue can occur without warning and will often go unnoticed by the end user. One competitor sells a “reconditioning kit” to address this issue; however, the user must proactively check to see if each sample remained bridged as there is not a warning to indicate when there is a problem.

DeNovix Spectrophotometer Advantages

0.5 mm Pathlength

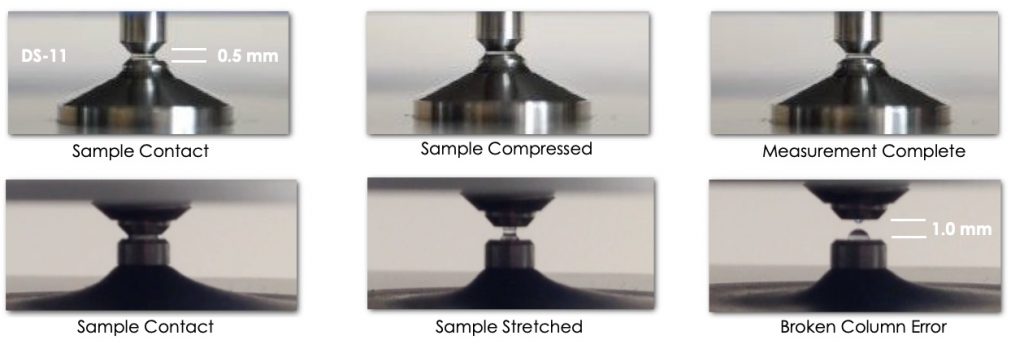

DS-11 and DS-8X instruments use a 0.5 mm path and compresses a sample during measurements, giving them an inherent advantage over other microvolume spectrophotometers that use a 1.0 mm path. Other spectrophotometers must stretch the sample to bridge the 1.0 mm gap. Making a measurement with an unbridged sample due to unconditioned surfaces or after a pipetting misload can lead to erroneous results when using instruments that rely on stretching the sample.

SmartPath Technology with Bridge Testing Verification

The DS-11 and DS-8X software includes a proprietary algorithm to test for an unbridged condition in the dsDNA, ssDNA, RNA and Protein A280 apps. This element of the SmartPath algorithm not only detects the unbridged condition, but it also compensates to ensure accurate results with no user action required.

Table 1 presents results of 0.5 μL dsDNA measurements taken on properly conditioned surfaces using the DS-11 dsDNA app and a competitor product to simulate misloaded 1.0 μL samples. The data shows that ten out of ten samples were measured accurately on the DS-11, whereas the competitor product gave erroneous results in nine out of ten replicates under the same conditions.

| Replicates | DS-11 Series (ng/μL dsDNA) | Competitor (ng/μL dsDNA) |

|---|---|---|

| 1 | 639.7 | 383.5 |

| 2 | 638.7 | 352.7 |

| 3 | 641 | 617.3 |

| 4 | 645.9 | 232.1 |

| 5 | 648.2 | 360.1 |

| 6 | 645.2 | 392.9 |

| 7 | 645.3 | 395.7 |

| 8 | 639.3 | 362.6 |

| 9 | 644.4 | 368.7 |

| 10 | 645.2 | 380.6 |

| Average | 643.3 | 384.6 |

| %CV | 0.51% | 24.5% |

| % Error | 1.42% | 39.43% |

Summary

Incorrect data associated with unbridged sample measurements is a common problem many users of microvolume spectrophotometers are unaware they are encountering. DeNovix DS-11 and DS-8X instruments, using SmartPath technology with Bridge Testing verification, eliminate concerns associated with unbridged sample errors.

This innovative feature makes DeNovix spectrophotometers ideal for laboratories working with nucleic acids and proteins, enabling researchers to have the highest confidence that their microvolume measurement data is accurate.

23-APR-2025